We provide programming services in PLC and DCS, visualization applications like SCADA and HMI and for industrial measuring equipment.

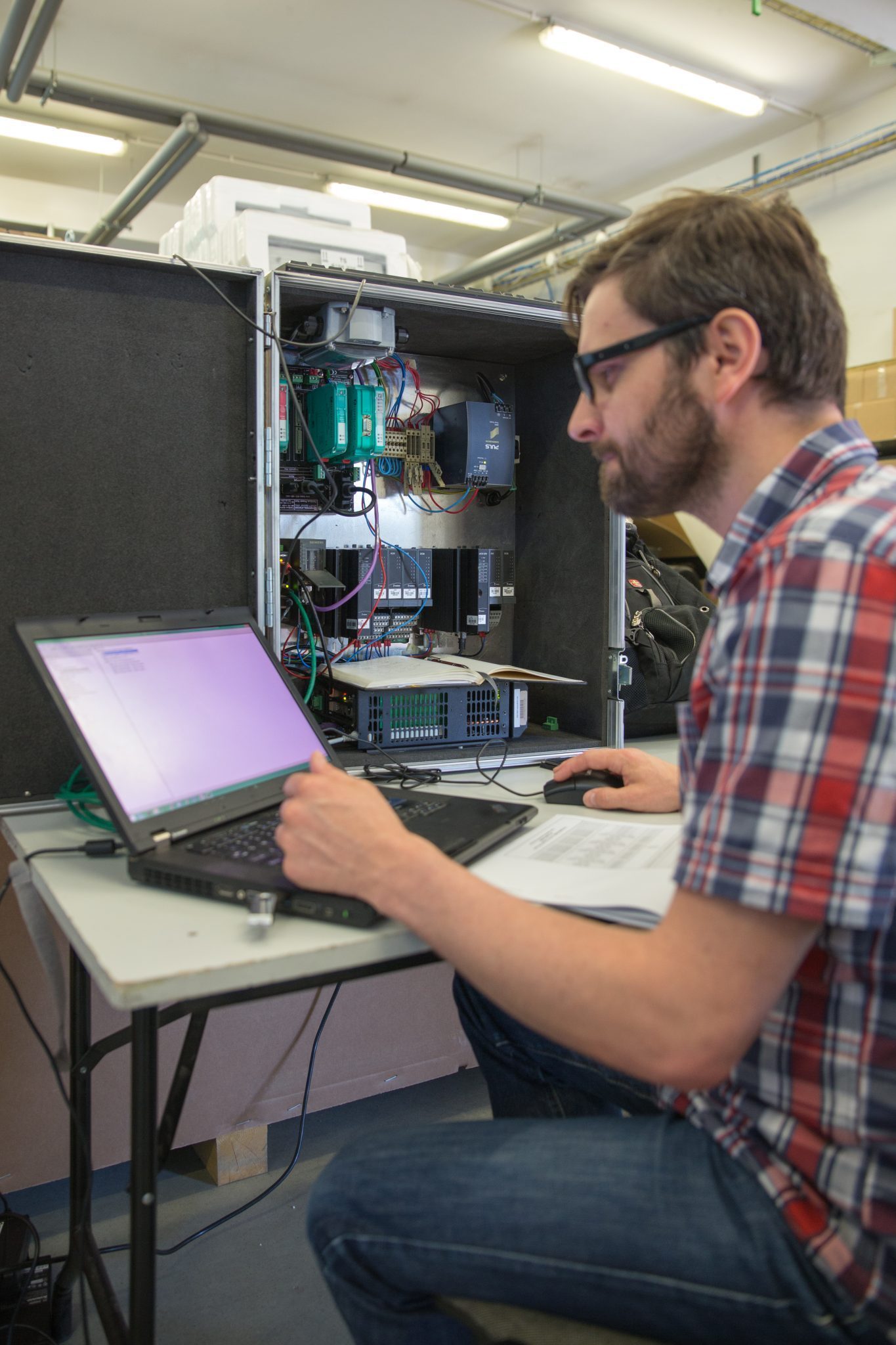

PLC and DCS programming

Thanks to a team of experienced programmers and young talented automation engineers, we can offer advanced and ergonomic software applications for industrial control and automation of production. Our resume contains dozens of launched PLC applications, perfectly handling thousands of I/O. Every program created and launched by us is characterized by reliability of operation, clear structure and an optimizing approach. Our solutions have been appreciated on big power plants as well as in complex control areas (e.g. waste treatment plants with fluidized bed, hard coal processing facilities).

SCADA and HMI visualization applications

Depending on the requirements and size of the facility we offer customized HMI and SCADA systems. Many years of experience and the precision of our employees result in creating a friendly and readable final product in the form of a human-machine or human-process interface. Additional functionalities such as archiving historical data, presenting them in the form of trends and graphs or generating automatic reports enable the user to benefit from the BIG-DATA wealth and minimize production costs.

- Siemens Simatic Step5/7

- Siemens Simatic TiaPortal

- Siemens WinCC

- Asix Evo

- ABB Freelance

- CopaData Zenon

- GE Proficy Machine Edition

- GE Proficy Cimplicity

- Mistubishi GXWorks

- Proface GP Pro-Ex

- Wonderware Archestra System Platform

- Wonderware InTouch

Industrial measuring devices

Measurements of the physical values are the basis of modern industrial process control. Selection of measurement transducers, delivery, creation and verification of assembly drawings (hook-up), loop-diagrams, device assembly and parameterization and acceptance testing are presented for a long time in Elsta’s specialist services portfolio.

Our accomplishments are, among others, the extremely responsible metering of the WP5 blast furnace cooling system for Arcelor Mittal Poland or the comprehensive measuring system of the Kujawy Sewage Treatment Plant in Cracow.